How to mix automotive and industrial paint

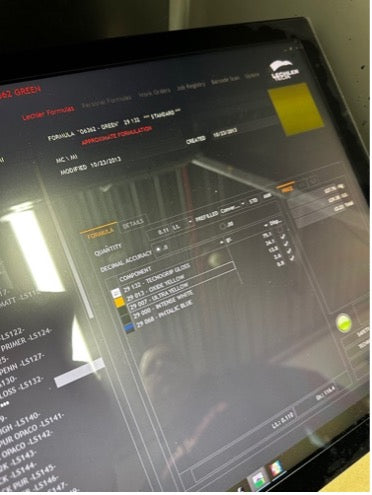

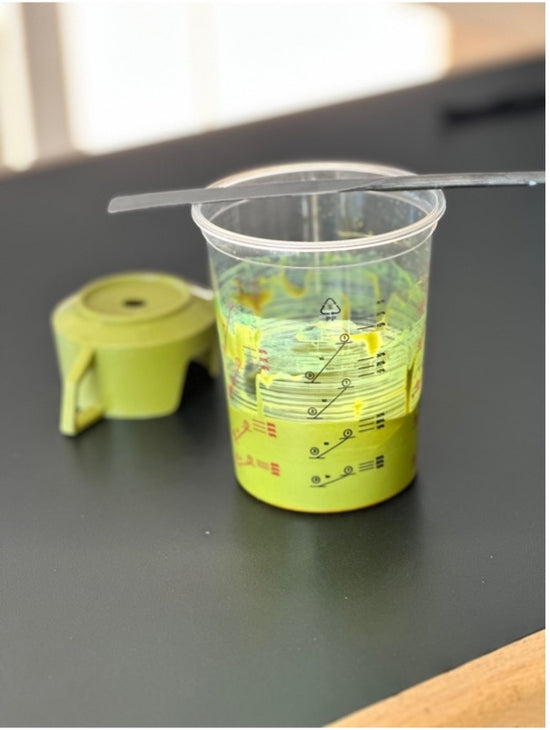

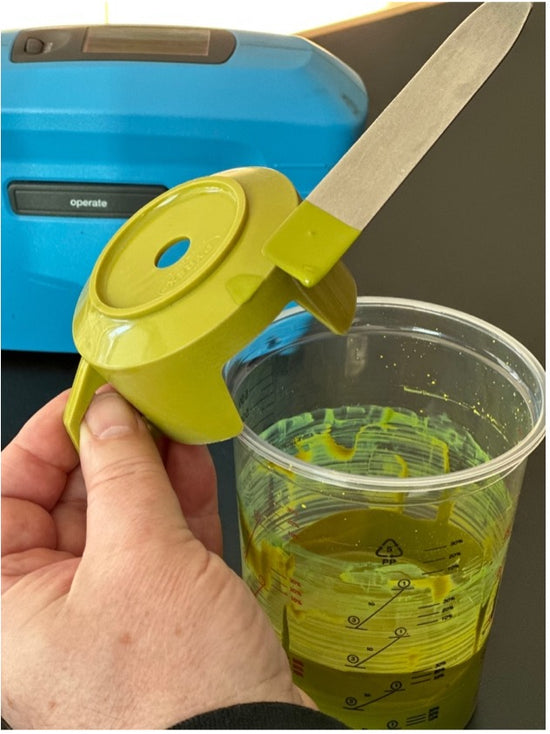

At Metalflake we have been mixing paint for over 50 years. Whether we’re preparing enough paint for a complete building, a full car respray or a 250ml tin to match a small area, our specialist paint consultants use the latest technology to ensure a perfect mix every time.

As well as supplying the automotive refinishing trade, Metalflake supplies paint mixes for a wide variety of other applications and projects including:

- Film and TV production

- Major construction/ infrastructure

- Agricultural machinery

- Sports equipment

- Musical instruments